Global-LocAl two-level Multi-scale optimisation strategy accOUnting for pRocess-induced singularities to design Variable Stiffness Composites

In recent years, additive manufacturing — also known as 3D printing — has made it possible to create materials and structures with very complex shapes and customized internal layouts. However, scientists and engineers still lack the right mathematical models and design tools to fully predict how these advanced materials behave under different conditions.

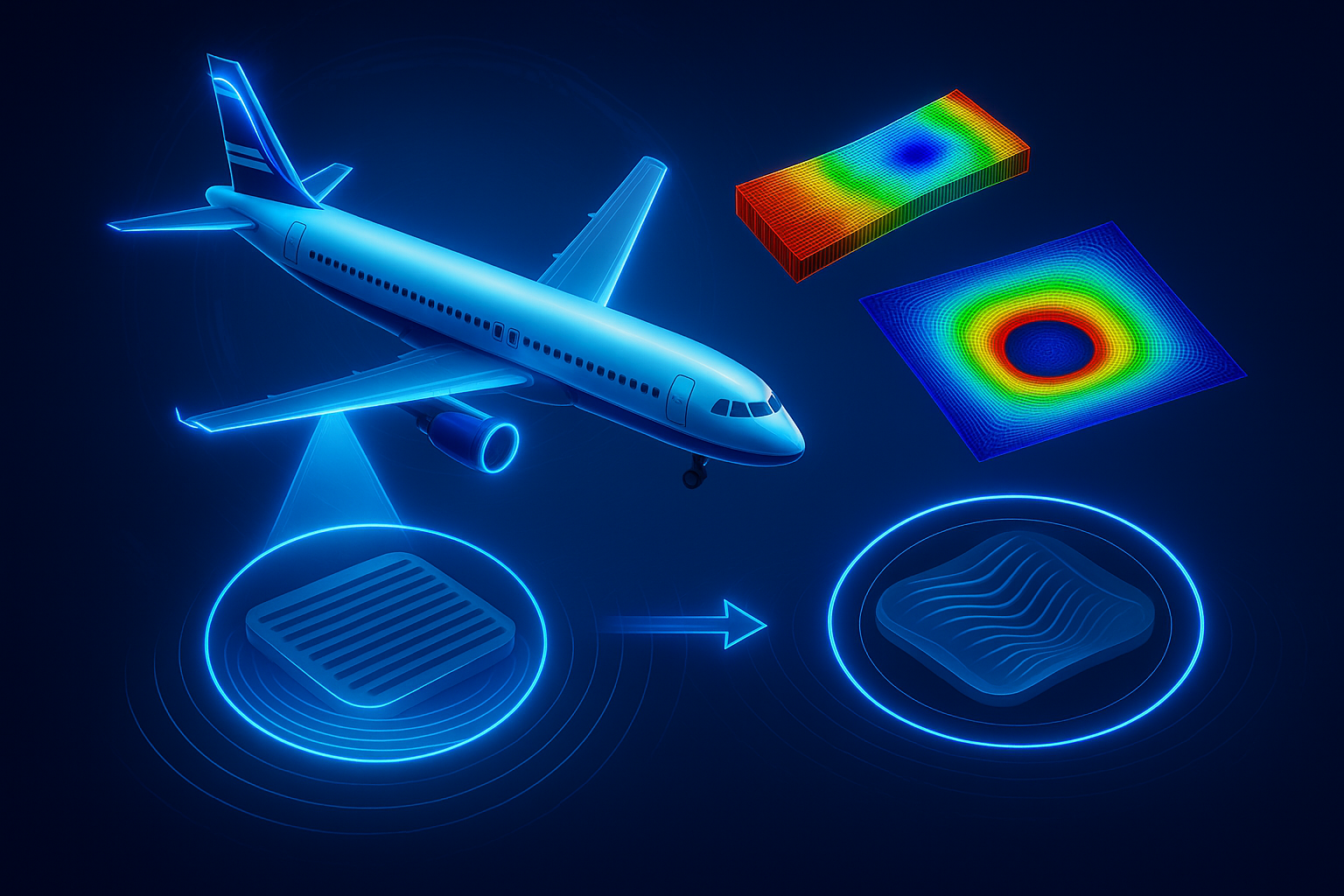

One exciting example is Variable Stiffness Composites (VSCs). These are materials whose stiffness can change from one area to another, allowing engineers to make parts that are both lighter and stronger where needed. Originally made using automated fibre placement, VSCs can now also be produced with additive manufacturing, which offers much greater freedom in how the material is arranged.

To design these advanced composites effectively, engineers need multi-scale approaches that consider the material’s behaviour from the microscopic fibres up to the full structure. They also need to account for small imperfections created during manufacturing — such as tiny air bubbles, micro-cracks, or areas with excess resin — since these can affect the overall performance of the part.

Although VSCs offer enormous potential, only a few studies have tried to optimize both their shape and fibre orientation at the same time, while also considering the effects of the manufacturing process. The GLAMOUR-VSC project aims to fill this gap by developing a comprehensive design framework and advanced modelling strategy that work across different scales — from the small details inside the material to the full structure. The goal is to create a powerful optimisation method and software tool that can find the best possible configuration of a VSC, balancing performance, manufacturing constraints, and process imperfections.

What makes this project innovative is its unified approach. It connects different scales of design and manufacturing, linking factors such as fibre paths and curvature limits with larger-scale properties like stiffness and shape. It also studies how manufacturing defects — such as small irregularities or weak spots — affect the overall strength and performance of the structure.

Another key novelty is the use of a global-local modelling strategy, which allows engineers to understand how small-scale effects influence the whole component. This method improves both accuracy and efficiency, making it possible to design optimal composite layers that are not only high-performing but also practical to manufacture. Through these advances, GLAMOUR-VSC aims to transform how engineers design and optimize next-generation composite materials.

The development of a global-local, multi-level optimisation strategy for VSCs is expected to bring major benefits to both research and industry. By considering the details of the manufacturing process from the very first design steps, this approach can save time and reduce costs across the entire product development cycle — from early design to prototype production.

Optimising how VSCs are designed will also make it possible to create lighter and stronger components, improving performance while reducing the overall weight of structures. At the same time, by accurately accounting for imperfections introduced during manufacturing, the method will help to increase the durability and safety of composite parts, reducing the likelihood of failure and improving their tolerance to damage.

Together, these advancements will have a direct impact on industry — leading to lower production and operational costs, reduced fuel consumption in transport applications, and less waste thanks to longer-lasting structures. Ultimately, the GLAMOUR-VSC project contributes to a more sustainable and efficient future for composite materials and their applications.