The increasing demand for lightweight, multifunctional, and sustainable materials is driving transformation across sectors such as aerospace, automotive, defense, and emerging mobility technologies. Industries face mounting pressure to reduce environmental impact, optimize performance, and implement digital and automated solutions throughout the lifecycle of composite structures.

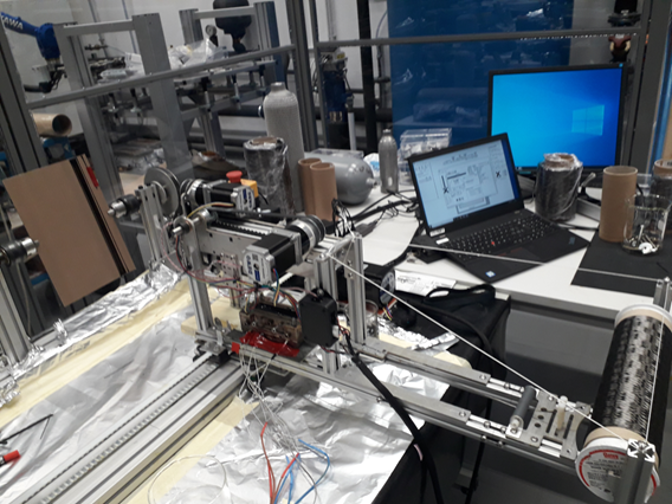

The Advanced Composite Manufacturing and Testing group is dedicated to tackling the challenges of manufacturing high-performance, multifunctional and sustainable composite components. Its activities span the entire lifecycle of composite structures, with a focus on performance optimization and advanced manufacturing processes. Research efforts combine unconventional and disruptive approaches, along with process development, modelling and engineering.- By integrating cutting-edge material solutions and innovative manufacturing methods, the groups aim to enhance performance, functionality and sustainability. This includes embedding Industry 4.0 and digitalization technologies with collaborative processes such as additive manufacturing, advanced composite fabrication and innovations in welding and assembly techniques. The advancements are designed to improve precision, quality control, scalability and efficiency in terms of cost, energy and material usage.

These advancements are designed to improve precision, quality control, scalability, and efficiency in terms of cost, energy, and material use. Equally important is the balance between high-performance requirements and affordability, alongside efficient end-of-life management through optimized assembly/disassembly and recycling strategies. All research is supported by the development of experimental techniques for material characterization, testing, and performance prediction.

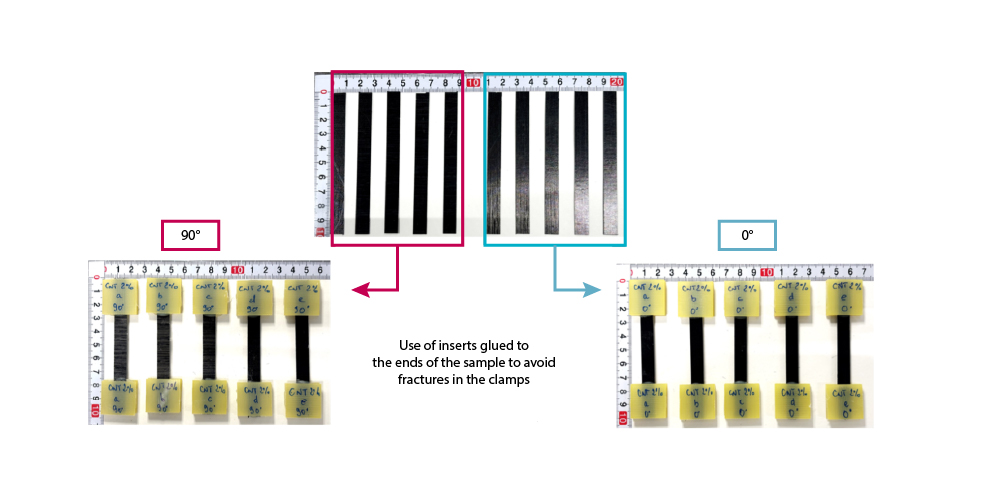

Development and Optimization of Variable Cross-Section Pultrusion for the Manufacturing of High-Performance and Sustainable Composites

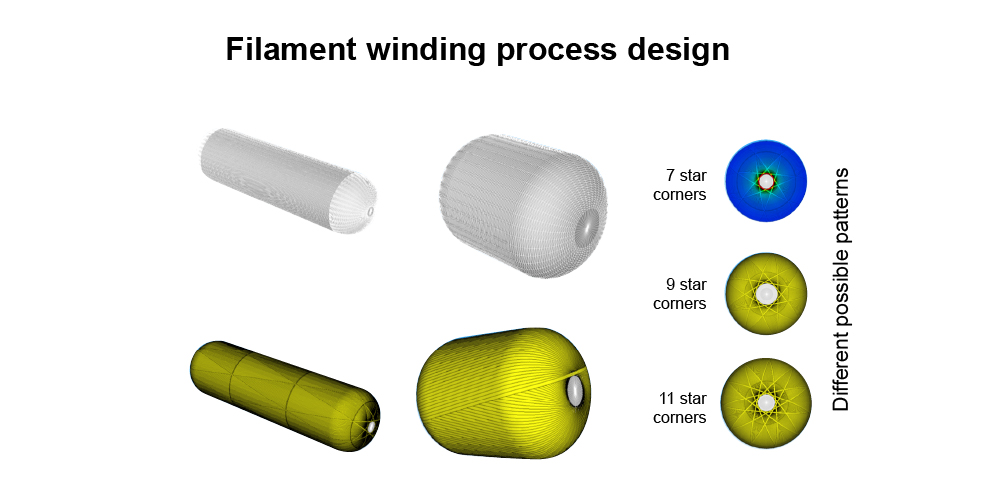

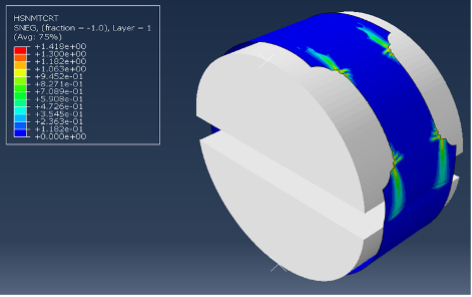

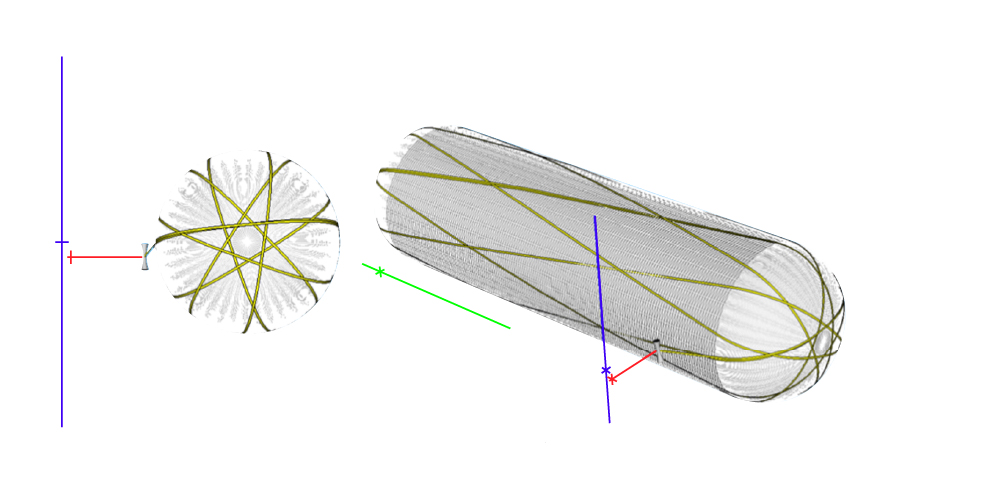

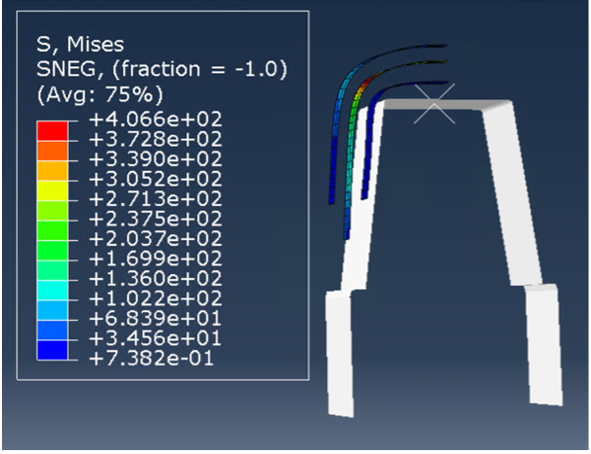

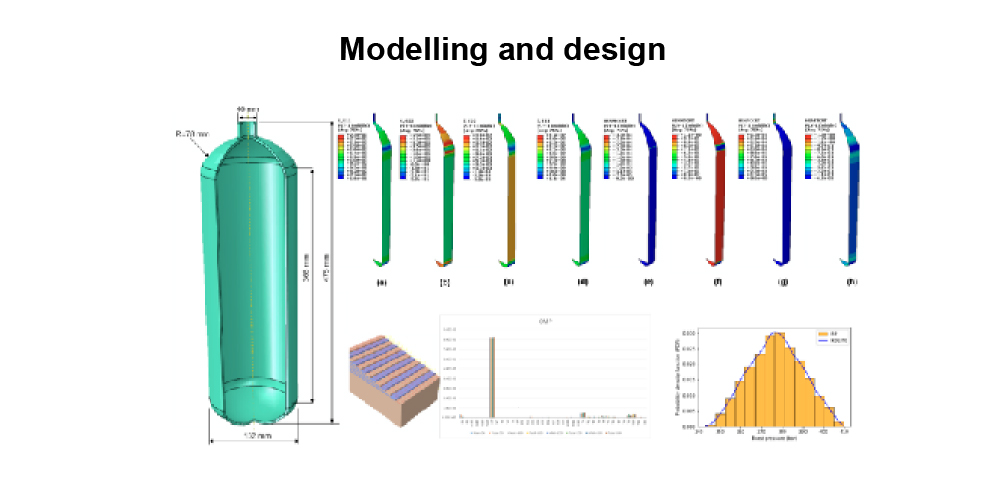

Safe Composite Pressure Vessels with Self Structural Health Monitoring Capacity

Safe Composite Pressure Vessels with Self Structural Health Monitoring Capacity

Laachachi A., Kachouri O., Berndt J., Zucker G., Zopp C., Bartelt J., Makradi A.

Journal of Advanced Joining Processes, vol. 13, art. no. 100369, 2026

Structure, Conformations, and Diffusion in PDMS/Silica Nanocomposites via Atomistic MD Simulations

Karatrantos A.V., Clarke N., Bouhala L., Mugemana C., Kröger M.

Macromolecules, vol. 58, n° 23, pp. 12429-12439, 2025

Izadi R., Wagner D., Michel A., Albrechtsen Y., Löpitz D., Zopp C., Drossel W.G., Lies C., Basaran M., Belouettar S., Makradi A.

Composites Part B Engineering, vol. 307, art. no. 112828, 2025