The growing demand for lightweight, durable, and sustainable materials is reshaping sectors such as automotive, aeronautics, aerospace, construction, and textiles. Industries are under increasing pressure to replace resource-intensive materials, reduce environmental impact, and develop next-generation solutions that combine high performance with circularity. Meeting these challenges require advanced fibre engineering and semi-finished products that deliver enhanced performance, functionality, and recyclability of composite materials.

The group is dedicated to advancing composite innovation by focusing on cutting-edge solutions in fibre engineering, surface and interface customization of reinforcements, fibre-based intermediates, and composite semi-finished products.. Research spans the entire development chain: from the extraction or synthesis of (natural) fibres to their engineering, incorporating advanced coating technologies to improve performance and durability, while enabling on-demand debonding and structural disassembly as well as their efficient combination with polymers to create fibre-based semi-finished products.

The group’s work focuses on a wide range of materials designed to tailor interface performance: synthetic and natural reinforcing fibres, thermoplastics, thermosets and functional hybrid organic thin coatings/sizing. These innovations are supported by advances in modelling tools, characterization and testing methodologies, which are specific to the technological building blocks—constituents and interfaces—of the developed materials.

Activities encompass the characterization, design and development of sustainable fibre-reinforced polymer composites, with a focus on performance tailoring of interfaces / interphases and natural fibres.

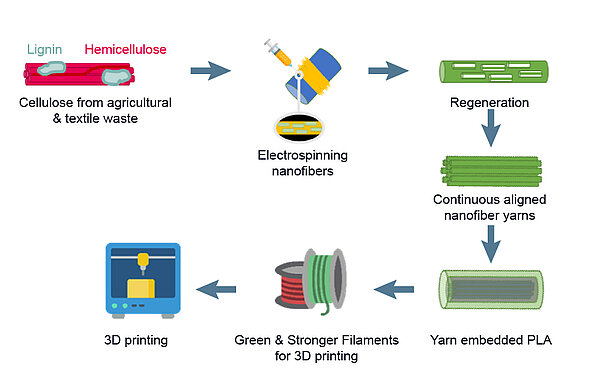

Cellulose from waste and bacteria in electro-spinning for continuous fibre reinforced 3D printed composites

Inorganic interfacial region in ultrathin copper foil supported by copper carrier: Resolving and controlling adhesion mechanisms

Hybrid Anti-Bacterial Coating

Laachachi A., Kachouri O., Berndt J., Zucker G., Zopp C., Bartelt J., Makradi A.

Journal of Advanced Joining Processes, vol. 13, art. no. 100369, 2026

Mugemana C., Cardona C.I., Ozyigit S., Hao J., Grysan P., Delfrari D., Dieden R., Verge P., Shaplov A.S., Ruch D., Fuentes C.A.

Composites Part A Applied Science and Manufacturing, vol. 203, art. no. 109578, 2026

Kara Y., Fuentes C.A., Huber T.

Materials and Design, vol. 262, art. no. 115385, 2026