Energy is one of the greatest challenges society will face in the coming decades. Modern life depends on access to energy, ideally from renewable sources. Materials can play a paramount role in proposing new solutions for clean energy access. These materials can be used for applications such as powering small sensors, harvesting waste heat and transforming it into electricity or enabling efficient electrocaloric cooling.

The Ferroic Materials for Energy Harvesting group studies piezoelectric and electrocaloric materials, which are respectively able to transform mechanical strain and heat into electricity. Its expertise is based on ceramic or polymer ferroic materials, which are developed into devices such as vibrating energy harvesters, pyroelectric harvesters and electrocaloric coolers.

The Ferroic Materials for Energy Harvesting group specialises in piezoelectric and electrocaloric ferroic materials, with expertise spanning their processing, characterization and integration into functional devices. This know-how supports the development of innovative solutions for energy harvesting and cooling, as reflected in the group’s main projects:

1. ELEC-FROM-HEAT – ERC Advanced (2024-2029)

Electrical energy represents about 20% of the global energy consumption, a share expected to rise to 40% by 2050 as reliance on non-renewable energies. While sunlight and wind are well-established renewable sources, heat is another formidable yet underexploited source of electrical energy. Currently, 72% of the energy produced worldwide is lost as waste heat, although up to 13,000 TWh could theoretically be recovered each year, equivalent to Europe’s annual energy demand.

In this context, the group recently demonstrated that 40 grams of nonlinear pyroelectric ceramics can generate more than 10 joules of electric energy from waste heat in a single thermodynamic cycle of 100°C. This output is one order of magnitude higher than the closest state of the art. The same materials were also shown to reach 40% energy efficiency with respect to Carnot’s efficiency – exceeding what photovoltaics and thermoelectrics can provide. These results raise a key scientific question:

: “Can this technology move beyond generating joules to delivering watts efficiently?”

The objective of this project is to show that energy harvesters made of nonlinear pyroelectric materials can generate 100 W of electric power from heat with 50% energy efficiency. To do this, (1) environmentally friendly nonlinear pyroelectric harvesting modules will be designed and fabricated, (2) the fundamental role played by specific phase transitions on the heat-to-electricity thermodynamic conversion in such materials will be analysed, (3) a power generator based on these harvesting modules will be developed with enhanced heat exchange capabilities able to generate 100 W of electricity from heat, and (4) another specific heat-to-electricity generator will be prepared showing that conversion efficiency can reach 50%.

Ultimately, the project aims to deliver a compact, efficient and cost-effective technology capable of transforming waste heat into a major new source of electric energy.

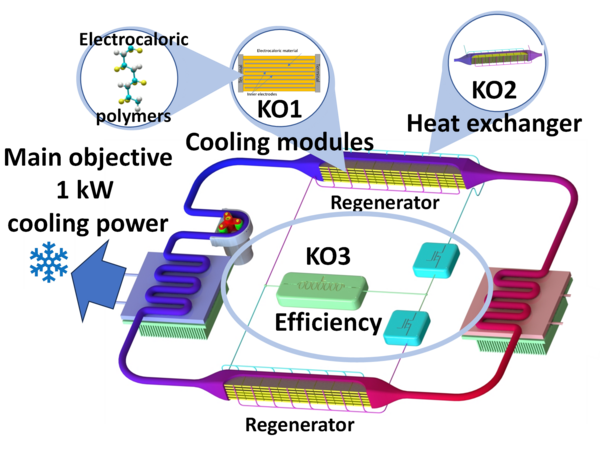

2. COOLPOL – EIC Pathfinder (2024-2028)

Cooling residential buildings and food storage currently consumes around 20% of all energy in the residential sector. This share is expected to rise to 40% by 2040 due to population growth and global warming. Existing cooling technologies are dominated by the vapour-compression system, a 150-year-old technology relying on greenhouse gases and exhibiting an average efficiency around 50%. This means that half of the energy used for refrigeration and air conditioning is lost as waste heat, highlighting the urgent need for cleaner and more efficient cooling principles.

Electrocaloric cooling has become an increasingly realistic alternative to vapour compression cooling. This principle is based on a reversible variation of temperature induced in specific materials when voltage is applied. LIST recently demonstrated that a few grams of electrocaloric ceramics can generate a temperature variation of 20.9 K and a cooling power of 4 W. Electrocaloric polymers, moreover, have a cooling potential one order of magnitude higher than ceramics.

The project aims to develop this, with a clear assessment of scale-up capabilities thanks to an ad hoc consortium. Hence, Arkema, world leader in electroactive polymers, investigates electrocaloric polymers able to reach a variety of temperatures higher than 5 K; KEMET, LIST’s European industrial partner, prepares thousands of multilayer capacitors based on optimized electrocaloric polymers; IAF, who recently published the most efficient energy recovery circuit for electrocalorics , builds electronic modules able to increase the efficiency of electrocaloric devices up to 60%, and finally, thanks to its extensive experience in making electrocaloric coolers, LIST assembles the multilayers and the electronic modules in a proof-of-concept aiming to reach a cooling power of 1 kW and an efficiency of 60%. If successful, this project will revolutionize cooling technologies.

3. SPACESENSE – INTER FNR-ANR (2022-2026)

The SPACESENSE project aims to develop a compact, versatile autonomous sensor system with energy storage devices, electronics and an RF antenna integrated for satellite monitoring. This 1 cm³ fully autonomous sensing and communicating system will combine three unique features: - (1) a temperature and strain sensor with a specific design directly printed on one face for intimate contact with the region of interest, (2) an original co-integration of the Li-S battery and supercapacitor for high-density energy storage and a dedicated ASIC for sensor signal processing, power management and a signal transmission module.

This last feature should eliminate the need for long prelaunch monitoring cables, which can extend up to 30km. As such, SPACESENSE will enable the installation of the minimally invasive Health and Usage Motoring System (HUMS) with broad applications, including motor, car, aircraft, helicopter rotors, gear motors, agricultural machinery and industrial conveyor belts. The sensor system suitability will be demonstrated for in situ temperature and strain measurement during pre-qualification ground tests of satellites.

Highly transparent lead-free piezoelectric haptic device

Song L., Glinsek S., Alluri N.R., Kovacova V., Melchiorr M., Martinez A.B., Mandal B., Cardoletti J., Defay E.

Communications Materials, vol. 6, n° 1, art. no. 91, 2025

Converting heat to electricity with non-linear pyroelectrics: A review

Aravindhan A., Kovacova V., Defay E.

International Materials Reviews, vol. 70, n° 7, pp. 576-611, 2025

Sharma S., Santiago A., Martinez-Ibañez M., Gerard M., Kumar A.S., De Castro O., Wirtz T., Eswara S.

Electrochimica Acta, vol. 536, art. no. 146728, 2025